How to install attic ventilation

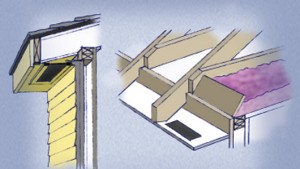

If you don’t install attic ventilation, it won’t be possible to minimize the difference in temperature between the attic space and the air outside. Without it, in the summer trapped heat can increase energy costs. Equally important, asphalt shingles deteriorate faster when subjected to greater temperatures from roof decking that overheats. Poor ventilation in an attic also condensation to develop as moisture vapor produced by clothes washers and dryers, dishwashers, and bathtubs and showers rises. If it’s bad enough, condensation can compromise roof insulation and rot the wood structure, especially plywood sheathing.

In cold climates,if you don’t install attic ventilation, a poorly ventilated attic can result in ice dams at the edges of the roof caused when snow melts from warmer areas of the roof and refreezes at the cooler eaves. The ice dams back up under the shingles, resulting in leaks in the attic or exterior walls.

Slip a pry bar between the shingles and separate the self-sealing adhesive. Then remove any shingle nails that prevent the vent from sliding into place.

How many vents needed for adequate ventilation

To ventilate an attic, you must determine how many intake vents will be needed at the eaves to allow fresh air into the attic, and how many exhaust vents are needed near or at the ridge of the roof to allow air to escape. This combination allows wind pressure and thermal effects to ventilate the area.

Coat the inside of the vent base with plastic roof cement and slip the base into position over the hole. The top flashing should be slipped under the shingles above the hole and lap over them below the hole.

To calculate how much venting to install to ventilate an attic, first determine the area of the vent that actually ventilates. An opening of 12 inches by 12 inches provides 144 square inches of potential ventilation area. However, after subtracting for blockage that results from louvers, insect screens or other obstructions, the actual ventilation area can decrease 60 percent or more. That’s the Net Free Vent Area, which is used to calculate how many vents are needed.

For our example, we’ll assume each vent has a Net Free Vent Area of 54 square inches.

Most attics requires 1 square foot of Net Free Vent Area for every 300 square feet of attic floor space. To determine the total attic floor space, calculate the area of the attic floor, then add the area of the garage (if there is an attached garage) and the area of the soffited overhang.

For our example, we’ll use an 1,800-square-foot home with a garage measuring 20 by 22 feet. The total area is 2,240 square feet. Divide that by 300 (2,240 ÷300 = 7.5) and proper ventilation will be accomplished with 7.5 square feet of venting.

(Note: Although Federal Housing Authority Guidelines recommend the “1/300 rule,” building codes in some areas require 1 square foot of Net Free Vent Area for every 150 square feet of attic floor space. If that’s true in your area, divide the total attic floor space by 150.)

Attic vents are measured in square inches. To convert the ventilation requirement from square feet to square inches multiply by 144 (1 square foot = 144 square inches).

For our example, multiply 7.5 square feet of venting needed by 144 (7.5 x 144 = 1,080). You need 1,080 square inches of Net Free Vent Area.

Intake and exhaust vents are usually installed at a 1:1 ratio—1 intake vent for each exhaust vent.

For our example, divide 1,080 by 2. We need 540 square inches of Net Free Vent Area in intake vents and 540 square inches of Net Free Vent Area in exhaust vents. Because the Net Free Vent Area in our example vent is 54 square inches, we want to install 10 intake and 10 exhaust vents. (Note: The Home Ventilating Institute recommmends a 60/40 ratio, or 60 percent of the total ventilation for intake vents and 40 percent for exhaust. To use a 60/40 ratio, multiply 1,080 by .60.)

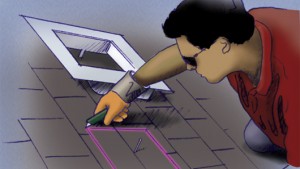

To install intake vents, lay out the location of the vents between the rafters, then cut the holes with the circular saw blade set to a depth about 1/8-inch greater than the thickness of the soffit.

How to install an intake vent

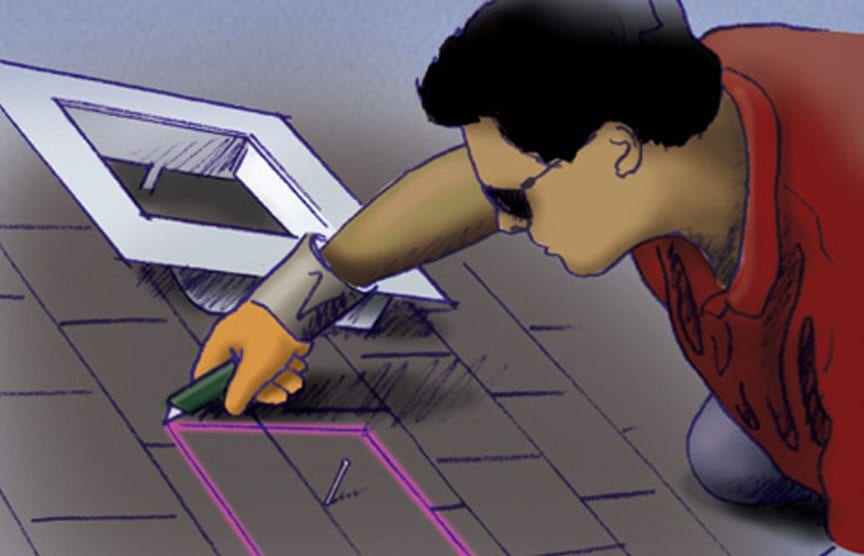

To install intake vents, lay out the locations between the rafters, then cut the holes with the circular saw blade set to a depth about 1/8-inch greater than the thickness of the soffit (soffit materials are usually ¼-inch thick). Screw the vent to the soffit.

If there is fiberglass blanket insulation in the attic, leave at least 1 inch of space between the top of the insulation and the underside of the roof sheathing. Otherwise, the insulation will block the airflow and the vents will be useless. If there is loose fill insulation in the attic, install baffles in each rafter cavity that has a vent to keep the air space clear.

Always leave at least 3 feet of vertical distance between intake vents and exhaust vents.

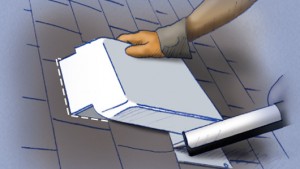

How to install an exhaust vent

To install roof-line exhaust vents, cut away the shingles and felt paper from the roof using a utility knife. The vent should be located between the rafters. Then use a saber saw to cut a hole in the roof the same size as the throat of the vent.

Coat the inside of the vent base with plastic roof cement and slip the base into position over the hole. The top flashing should be slipped under the shingles above the hole and lap over them below the hole. Nail the base in place with 1-1/2-inch galvanized roofing nails. Cover nail heads with roof cement.

—By Steve Sturgess

Tool and material checklist

- Intake vents

- Steel tape measure

- Utility knife

- Screwdriver

- Saber saw

- Putty knife

- Screws

- Ladder

- Exhaust vents

- Hammer

- Circular saw

- Plastic roof cement

- Nails

- Eye protection