Add basic welding to your list of skills

With proper training and focus on safety, basic welding is a useful and valuable skill for any small contractor. The ability to repair broken equipment, make non-structural connections or fabricate useful accessories can save time and money. The most commonly used basic welding methods are arc or stick, MIG, flux-cored, braze and TIG.

Arc welding, also known as stick welding, uses electricity to create an arc between the metal being welded and a consumable electrode known as a stick. When energized the arc melts the electrode to create the weld ”puddle” or liquid metal that flows to the joint being welded. Arc welding is typically used when welding materials 3/8 inch or thicker. Arc welding produces a lot of smoke so is typically performed outdoors.

Wire welding, commonly called MIG welding, uses a gun that feeds a solid steel wire through an electrically charged contact tip that melts the wire to create the weld puddle. MIG welding is common for materials between 22 gauge and ¼-inch thick and is best used for interior work.

Flux-cored arc welding is similar to MIG. However, it’s more forgiving than MIG and more portable. With flux-cored, the welding machine must be in close proximity to the work (within 10 feet). Flux-core works with the same type of wire as MIG welding, so some machines work for both MIG and flux-cored.

Braze welding is closer to soldering in that the metal parts are actually not melted together, but instead are heated until red-hot and a braze filler rod is melted to act as a bonding agent. Brazing is used for small parts or to join dissimilar metals and requires tanks of compressed oxygen and acetylene.

TIG welding is a high-quality welding process used when precision is required. In TIG welding, an arc is formed between a non-consumable tungsten electrode and the metal being welded. TIG welding requires a higher level of skill and is more costly.

[tip id=”10610″]Basic welding safety

Safety precautions are relatively the same regardless of the type of welding you’re doing. The extremely high temperatures required for welding create a serious fire hazard. The basic safety protocols necessary for welding require that you always keep a properly charged fire extinguisher within close reach and remove all flammable items and liquids from the area. In addition, never weld alone, unless the risk of fire is very minimal.

The welding environment and equipment can present additional risks. Always read and understand all directions related to the welding machine you plan to use and follow these basic precautions before welding:

- Make sure your work area is free of clutter and tripping hazards

- Establish a sturdy, fireproof work platform, bench or stand that will not tip or move during welding

- Use suitable clamps as needed to lock your materials in place

- Place all welding equipment and a fire extinguisher in a useful location where they can be reached easily

- Ensure you have proper lighting and ventilation for the type of welding you are doing

- Communicate with others that welding is going to start, and if needed, set up signage or barricades to warn other tradesman that welding is underway so no one comes into the work area unprotected.

- Make sure all co-workers in the area are aware of the serious eye damage that can occur if they look directly at the welding arc

- Before doing anything with or to a welding machine, ensure that the last user disconnected the arc welder from its power source. If you cannot unplug the machine, cut the electricity to the arc welder at its source. Never inspect or perform maintenance on a machine that can power on

- Check all wires for damage or wear, and check all surfaces for damage. Do not use a visibly damaged machine

- A machine lacking a properly configured ground can cause severe electric shocks. The most usual arrangement for grounding an arc welding machine is to run a wire from the machine to a metal rod buried in soil.

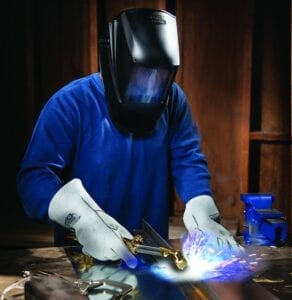

Personal protective equipment

Personal protective equipment (PPE) is a vital concern with all types of welding. In particular, the helmet is critical to avoid serious eye damage. The traditional dark glass lens helmet is functional, but it makes the welder basically blind until the arc or flame is ignited. Newer helmets are auto-darkening, but make sure you purchase a well-known brand. Goggles are also used, but wear a hardhat to protect your hair.

Heavy gauntlet-type leather gloves are a must to be sure your hands and forearms are protected from heat and stray sparks. Also, wear a long-sleeved shirt or jacket with the collar buttoned and pants that do not have cuffs. Make sure you clothing fits close to the body and is flame resistant or, at a minimum, use heavy cotton materials. Do not wear synthetics.

Your clothing should be dry, water resistant and free of holes. Empty your pockets of lighters or other flammable items. And always wear heavy leather boots and a welder’s apron.

Many community colleges offer classes in welding. The Internet and local libraries are other excellent resources to learn the basics.

—By Bruce Webb, General Contractor