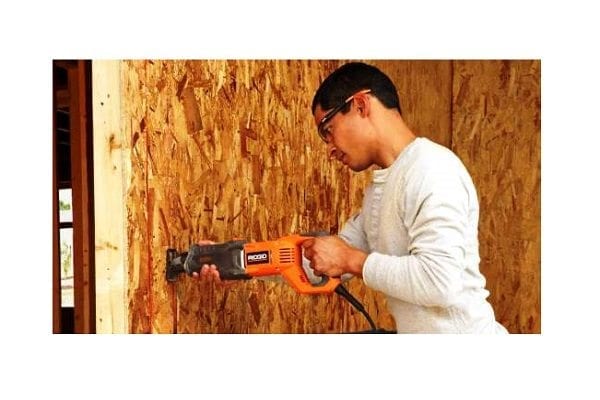

8 tips for using a reciprocating saw

Eight tips for using a reciprocating saw for residential remodeling, repair and restoration from John Painter, long-time home-improvement contractor and owner of New Jersey-based Enduring Charm .

Tip 1. Get creative with blades. Instead of using a traditional reciprocating saw blade when you have to delicately reach behind trim, rig your saw with a hacksaw blade instead. The hacksaw blade is especially thin, so if you’re working on an old house removing trim, for example, the thinner blade is easier to maneuver behind the trim so you can cut the nails.

To make it work, use a grinder to grind away the little notch on the end of the blade, and it will fit into a reciprocating saw. The benefit, Painter says, is the extra length of the hacksaw blades. The ends of a hacksaw blade and a reciprocating saw blade are similar.

Tip 2. A reciprocating saw can shave, too. Cutting and demolishing aren’t the only uses for reciprocating saws, Painter says. He uses a reciprocating saw to shave away humps and bumps in boards. “Structural lumber isn’t always as straight as you would like,” he says. So he positions the saw blade to make a glancing cut and shave off just a little bit of wood where needed to straighten out the member.

Tip 3. Remove nails. A common use for a reciprocating saw is to remove studs and other pieces of wood that have been nailed together. You can use a hammer to pull the nails out or to bash them in. But it’s often easier to cut through the nails—a job that’s fairly simple, Painter says, with a reciprocating saw. The benefit of using a reciprocating saw instead of manually extracting the nails, he says, is that you will barely damage the wood. He uses the saw in new construction, too, if pieces of wood are nailed together by mistake. The reciprocating saw will cut the nails so he can reposition the stud and re-nail it.

Tip 4. Embrace the plunge cut. It’s typical to use a circular saw to cut holes in a floor for plumbing access. But a reciprocating saw works just as well, Painter says. He advises making plunge cuts to surgically locate openings or remove plywood flooring. His method: Start in the middle, using the blade face-up. That is, load the blade upside down in the saw. Pivot into the cut, using the tool itself to line it up with a line you have pre-drawn. “You can get fairly accurate with this,” says Painter, who calls the technique “very useful for remodeling.” His reason: Controlling the depth of the cut with a reciprocating saw is easy because the operator can see the blade as it pivots through the wood. “You can actually see the blade in the wood as you go,” Painter says, “so you actually know how deep you are. You just watch the blade in the saw to determine depth.”

Tip 5. One of the most popular tips for using a reciprocating saw is to take the saw outdoors. Painter uses his reciprocating saw outdoors to remove clapboard siding. He suggests orienting the blade to face sideways, a position that allows him to get the blade close enough to slip underneath the clapboard and cut the nails off. Instead of removing small pieces of siding, he can pry it off in larger sections. The sideways position works the same way on exterior and interior trim. Using a metal cutting blade to cut through the nails, the trim pulls of easily and saves him from trying to pry it off with a hammer—which can damage the wall.

Tip 6. Vary the speed. Choose a reciprocating saw with a variable-speed trigger—and then learn how it works before trying it out on the job, Painter advises. “It’s very important to understand the different speeds that are appropriate for what you’re trying to cut,” he says. For example, when you’re cutting metal, the saw blade tends to heat up quickly, so you should use a slower speed. “Getting some familiarity with the trigger so you can do a slow speed when you cut is critical,” he says.

Painter notes that he begins his cut “very slow; the blade churns slow” when cutting metal or making plunge cuts. But for other cuts, he chooses a faster speed. Either way, a variable-speed model allows him to choose.

Tip 7. Included in the list of 8 tips for using a reciprocating saw is to buy a light saw. Heavier, Painter says, isn’t necessarily better, especially for contractors who use the equipment all day or who need to maneuver into tight spots.

Tip 8. Buy quality blades. “Cheap blades make for frustration” Painter says, because “they snap easily.” He suggests buying blades made by well-known manufacturers. The cheaper the blade, he says, the more often you’ll need to change it, which costs money and time on the job.